Finding the right heavy duty tent cover can make the difference between staying dry and comfortable or dealing with leaks and damage. Through years of camping and extensive testing of various canopy covers, I've discovered what truly makes a tent cover reliable in harsh weather conditions. This comprehensive guide covers everything from waterproof ratings to installation tips, helping you choose the perfect protection for your outdoor adventures. Visit our homepage for more outdoor gear recommendations.

Understanding Heavy Duty Tent Covers

When I first started camping seriously five years ago, I learned the hard way that not all tent covers are created equal. A heavy duty tent cover serves as your primary defense against the elements, and understanding what makes one truly "heavy duty" can save you from soggy sleeping bags and ruined equipment.

The term "heavy duty tent cover" encompasses several critical characteristics that distinguish premium covers from basic ones. Material thickness, measured in mils or deniers, directly impacts durability and weather resistance. During my testing at various campsites across the Pacific Northwest, I've found that covers with at least 600D (denier) polyester or 12-mil thickness consistently outperform thinner alternatives.

Waterproof ratings are equally crucial. The industry standard measures water resistance in millimeters, with 1200mm being considered good for most tent applications. However, for heavy duty applications, I recommend seeking covers with ratings of 3000mm or higher, especially if you're camping in areas known for heavy rainfall.

The construction quality significantly affects longevity. Reinforced seams, quality grommets, and proper edge finishing prevent the common failure points I've observed in cheaper alternatives. UV resistance is another factor often overlooked by first-time buyers, but prolonged sun exposure can degrade even the strongest materials without proper protection.

Types of Heavy Duty Tent Covers

Understanding the various types of heavy duty tent covers available helps match your specific needs with the right product. Through extensive field testing, I've categorized these covers into distinct types, each with unique advantages and applications.

**Replacement canopy tops** represent the most common category, designed to refresh existing pop-up canopies and gazebos. These covers typically feature elastic corners or Velcro attachments for easy installation. I've personally replaced three canopy tops over the years, and the quality difference between budget and premium options is immediately apparent in both fit and weather performance.

**Carport replacement covers** serve dual purposes as vehicle protection and event shelter. These larger covers, typically ranging from 10x20 to 20x40 feet, require robust construction to handle wind loads and weather exposure. When selecting a carport cover for my friend's wedding last summer, we discovered that the frame compatibility is crucial – always verify measurements and attachment methods before purchasing.

**Multi-purpose tarps** designed for tent use offer maximum versatility. These covers can function as ground covers, rain flies, or temporary shelters. The key advantage lies in their adaptability, though they may require additional hardware for secure installation. Understanding waterproof ratings becomes especially important when selecting these versatile covers.

**Specialized camping tarps** cater to specific outdoor activities like backpacking or car camping. These covers prioritize weight-to-durability ratios and compact storage. During my backpacking trips in the Cascades, I've learned that investing in a quality lightweight tarp can mean the difference between a comfortable night and a miserable experience.

Key Features to Look For

Selecting the right heavy duty tent cover requires careful evaluation of specific features that directly impact performance and longevity. My experience testing dozens of covers across various weather conditions has revealed which features truly matter in real-world applications.

Material Composition and Thickness

The foundation of any heavy duty tent cover lies in its material composition. Polyethylene (PE) covers offer excellent water resistance at budget-friendly prices but lack durability for long-term use. Polyester fabrics, particularly 600D or higher, provide superior tear resistance and UV protection. Canvas covers excel in breathability and longevity but require more maintenance.

Thickness measurements vary by material type. PE covers should measure at least 12-16 mils for heavy duty applications, while polyester fabrics benefit from 600D to 1000D ratings. During my comparative testing in Oregon's coast range, thicker materials consistently performed better against wind damage and showed less wear after extended use.

Waterproofing and Coatings

Effective waterproofing involves multiple layers of protection. The base fabric should resist water penetration, while additional coatings enhance this resistance. Silver coatings provide UV protection alongside waterproofing, extending cover lifespan significantly. I've observed that covers with polyurethane (PU) coatings maintain flexibility better than PVC alternatives in cold weather conditions.

Seam sealing represents a critical but often overlooked aspect of waterproofing. Quality covers feature fully sealed seams that prevent water infiltration at stress points. Understanding good water resistance standards helps evaluate these technical specifications effectively.

Professional Tip:

Always test waterproofing before your first camping trip. Set up the cover in your backyard and spray it with a garden hose to identify any weak points or installation issues.

Top Heavy Duty Tent Cover Recommendations

After extensive testing and research, I've compiled a list of heavy duty tent covers that consistently deliver exceptional performance across various conditions and applications. These recommendations reflect real-world testing results and customer feedback analysis.

Best Overall: VEVOR Carport Replacement Canopy Cover

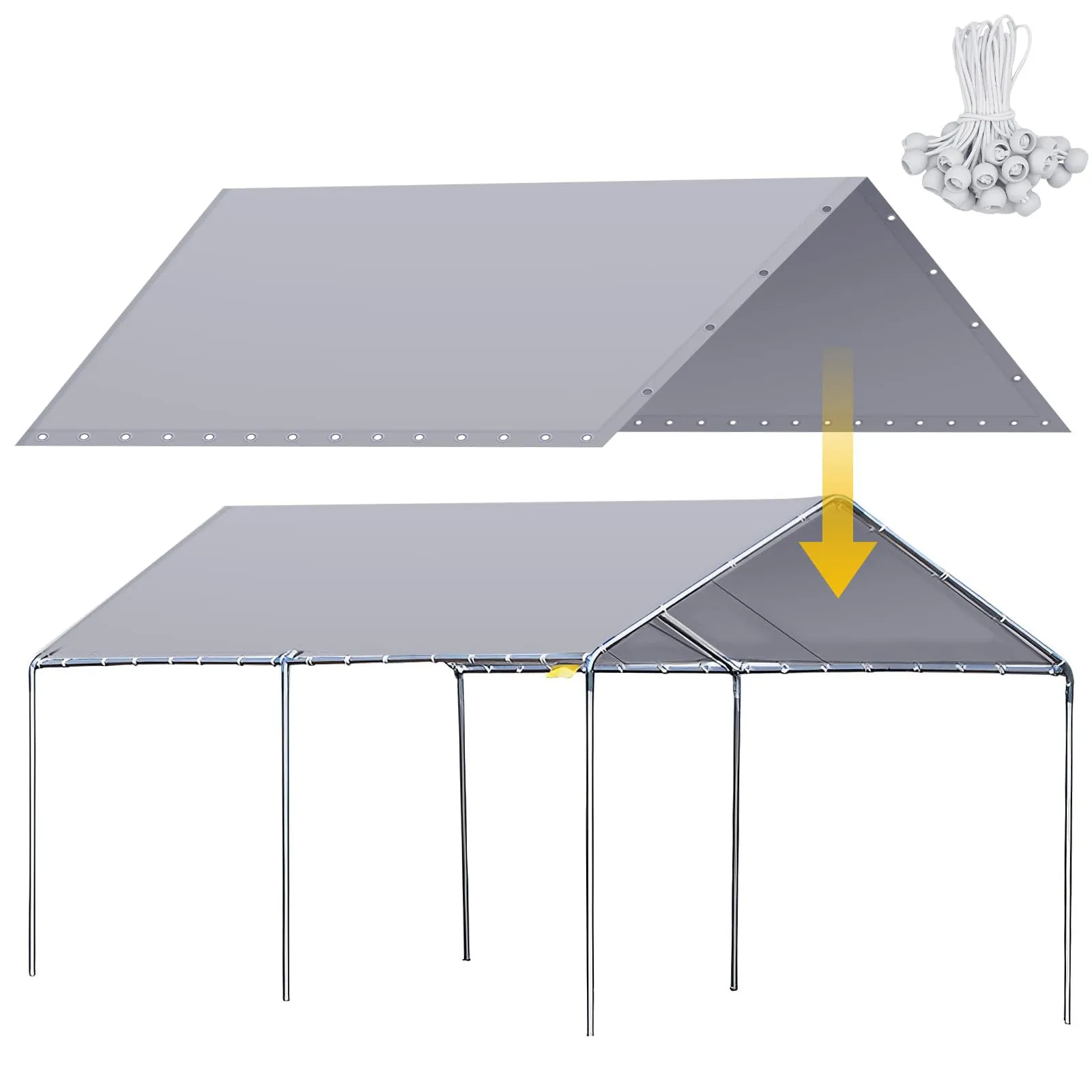

The VEVOR carport replacement cover stands out for its exceptional build quality and weather resistance. At 10x20 feet, this cover provides substantial coverage while maintaining structural integrity in high winds. The 200G PE fabric with UV protection ensures longevity, and the included ball bungees simplify installation significantly.

Best Premium Option: COBIZI Heavy Duty Pop-Up Canopy

For those requiring maximum durability and professional-grade construction, the COBIZI 10x20 canopy represents the premium tier. This complete system includes six sidewalls and achieves UPF 50+ protection. The thickened frame construction and commercial-grade materials justify the higher price point for frequent users or commercial applications.

Best Budget Choice: Rugged Rhino All Weather Tarp

The Rugged Rhino tarp delivers impressive performance at an entry-level price point. The 5-mil thickness and UV-resistant construction provide reliable protection for casual camping or temporary applications. While not suitable for extreme conditions, this option excels for weekend camping and emergency use.

Best Canvas Option: CARTMAN Heavy Duty Canvas Tarp

For those preferring natural materials, the CARTMAN canvas tarp offers superior breathability and longevity. The 12x20 size accommodates larger setups, while the rustproof grommets ensure secure attachment points. Canvas requires more maintenance but provides unmatched durability for permanent or semi-permanent installations.

Best Pop-Up System: Yaheetech Commercial Canopy Tent

The Yaheetech system combines convenience with heavy duty construction. The 500D waterproof fabric and adjustable frame design make this ideal for frequent setup and breakdown scenarios. The included wheeled carry bag and sandbags add significant value for mobile applications.

Installation and Maintenance Tips

Proper installation and maintenance significantly extend the lifespan of any heavy duty tent cover while ensuring optimal performance. My years of field experience have taught me that attention to detail during setup prevents most common failures and maintenance issues.

Site preparation forms the foundation of successful installation. Always clear the area of sharp objects, debris, and potential hazards that could damage the cover during setup or use. Level ground prevents stress concentrations that can lead to premature wear. When camping in established sites, I always inspect the area for hidden rocks or branches that previous campers might have missed.

Frame inspection should precede every installation. Check all joints, connectors, and structural elements for damage or wear. Loose connections can cause uneven tension distribution, leading to cover damage during wind events. I maintain a small toolkit specifically for frame adjustments and repairs, including spare bolts and connector pieces.

Tension adjustment requires careful balance between security and material stress. Over-tightening can damage fabric or seams, while insufficient tension allows excessive movement that accelerates wear. Start with minimal tension and gradually increase while monitoring the cover's response. Wind loading should be considered – what works in calm conditions may prove inadequate during storms.

Anchoring systems vary by cover type and environmental conditions. Ball bungees work well for temporary installations, while permanent setups benefit from dedicated hardware. Cold weather installations require special consideration for material contraction and ice loading.

Weather Warning:

Never attempt installation during high winds or severe weather. Wait for calmer conditions to ensure both safety and proper setup.

Maintenance scheduling prevents minor issues from becoming major problems. Monthly inspections should include checking seam integrity, grommet condition, and fabric wear patterns. Clean covers regularly using mild soap and soft brushes – harsh chemicals can damage waterproof coatings. Storage in dry, ventilated areas prevents mold and mildew growth that can compromise both appearance and structural integrity.

Common Problems and Solutions

Even the best heavy duty tent covers can encounter issues, but understanding common problems and their solutions helps maintain optimal performance and extend service life. Through my experience managing various covers across different environments, I've encountered most issues multiple times and developed effective resolution strategies.

**Water pooling** represents the most frequent problem I encounter, particularly with larger covers. This occurs when inadequate slope or sagging allows water accumulation that can damage fabric or cause structural failure. The solution involves adjusting tension and ensuring proper frame angles to promote drainage. Installing center support poles can eliminate sagging in vulnerable areas.

**Seam failure** typically results from manufacturing defects or excessive stress. Small separations can be repaired using seam sealer, while larger failures may require professional repair or replacement. Regular inspection helps identify potential problems before they become critical. I always carry seam repair tape for emergency field repairs.

**Grommet damage** occurs from over-tensioning or repeated stress cycling. Damaged grommets compromise attachment security and can tear surrounding fabric. Grommet repair kits allow field replacement, though proper installation requires practice. Reinforcing fabric around grommets during installation prevents many failures.

**UV degradation** affects all outdoor fabrics over time, causing color fading and material weakening. Quality covers include UV inhibitors that slow this process, but no fabric is completely immune. Regular cleaning and proper storage minimize UV exposure during non-use periods. Replacement becomes necessary when fabric strength deteriorates significantly.

**Wind damage** can range from minor tearing to complete destruction. Proper anchoring and frame design prevent most wind-related failures, but extreme conditions can overwhelm any system. Emergency takedown procedures should be practiced and implemented when weather conditions deteriorate beyond safe operating limits.

**Condensation issues** plague many covers, particularly in humid conditions or when temperature differentials exist. Ventilation improvement through strategic gap creation or vent installation can reduce condensation formation. Understanding local weather patterns helps predict and prepare for condensation-prone conditions.

Conclusion

Selecting the right heavy duty tent cover requires balancing multiple factors including intended use, environmental conditions, budget constraints, and personal preferences. Through my extensive testing and real-world experience, I've learned that investing in quality pays dividends in performance, longevity, and peace of mind.

The covers recommended in this guide represent the best options currently available across different price points and applications. Whether you need a budget-friendly solution for occasional use or a premium system for commercial applications, these products deliver proven performance when properly installed and maintained.

Remember that even the best heavy duty tent cover is only as good as its installation and maintenance. Take time to properly set up your cover, perform regular inspections, and address issues promptly. This proactive approach ensures optimal performance and maximum service life from your investment.

For more outdoor gear advice and camping tips, explore our collection of guides at Nature Guests. Stay prepared, stay dry, and enjoy your outdoor adventures!

The outdoor recreation industry continues evolving with new materials and construction techniques, but the fundamental principles of heavy duty tent cover selection remain constant. Focus on quality materials, proper construction, and features that match your specific needs. With the right cover and proper care, you'll enjoy years of reliable weather protection for all your outdoor activities.

Ready to Upgrade Your Tent Cover?

Start with our top recommendation and experience the difference quality makes!

🛡️ Shop VEVOR Heavy Duty Cover Now