The Complete Guide to Lightweight Waterproof Tent Material: Everything You Need to Know

After spending over a decade testing outdoor gear across various terrains and weather conditions, I've discovered that choosing the right lightweight waterproof tent material is crucial for any successful camping adventure. Whether you're a weekend warrior or a serious backpacker, understanding fabric technology can make the difference between a comfortable night's sleep and a soggy disaster. This comprehensive guide covers everything from fabric types to maintenance tips, helping you make informed decisions for your outdoor pursuits.

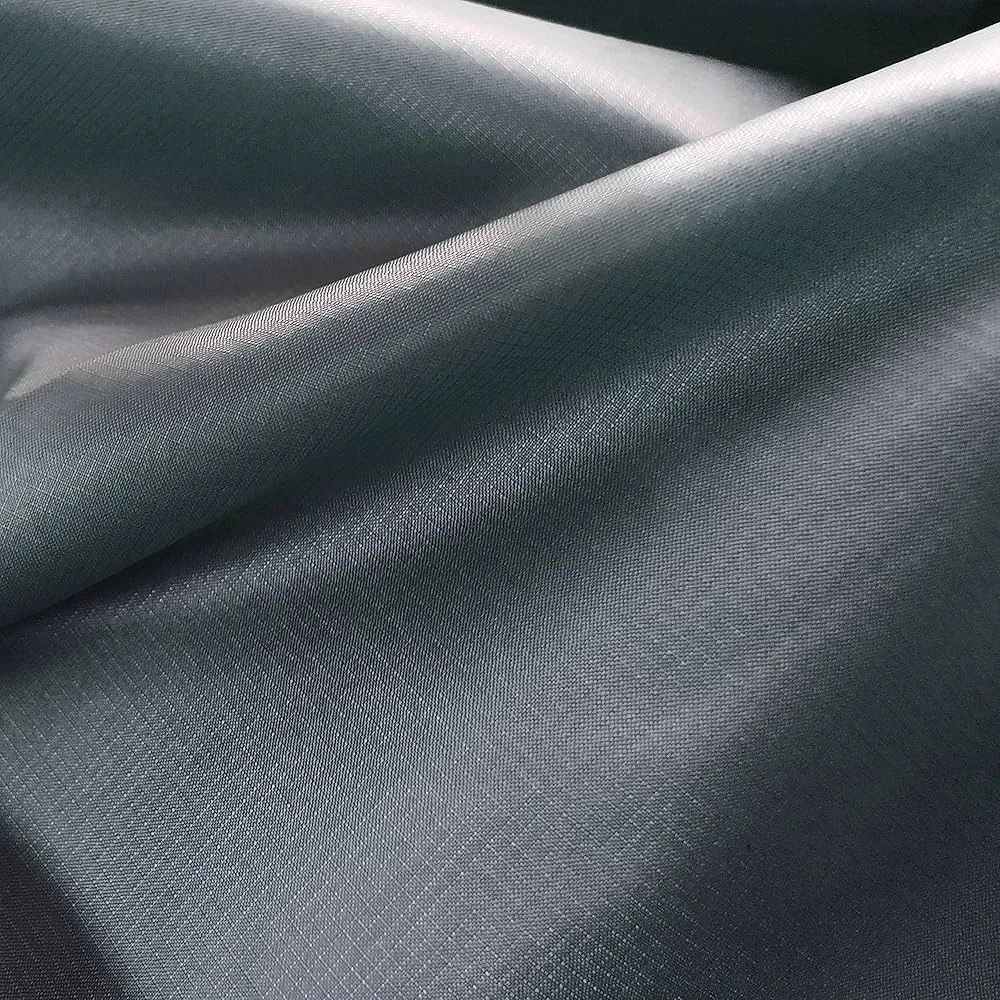

Understanding Lightweight Waterproof Tent Material

When I first started camping in the early 2000s, lightweight waterproof tent material was still a luxury reserved for expensive gear. Today, advanced fabric technology has made these materials accessible to every outdoor enthusiast. The key to understanding these materials lies in recognizing the delicate balance between weight, waterproofing, and durability.

Modern lightweight waterproof tent material typically weighs between 1.2 to 3 ounces per square yard, compared to traditional canvas tents that can weigh 10-15 ounces per square yard. This dramatic weight reduction comes from sophisticated manufacturing processes that create ultra-thin fibers while maintaining structural integrity through ripstop weaving patterns.

The waterproofing aspect involves applying specialized coatings or treatments to the base fabric. I've tested numerous materials during my camping expeditions across the Pacific Northwest, where relentless rain is a constant challenge. The most effective lightweight waterproof tent material combines a durable water repellent (DWR) finish with either polyurethane (PU) or silicone coatings for maximum protection.

What makes these materials truly remarkable is their ability to maintain breathability while blocking moisture. This prevents the condensation buildup that plagued older tent designs. During a particularly memorable backpacking trip through Olympic National Park, I witnessed firsthand how quality ripstop nylon materials can withstand sustained rainfall while keeping the interior completely dry.

Types of Waterproof Tent Materials

Silicone-Coated Nylon (Silnylon)

Silnylon represents the gold standard in lightweight waterproof tent material. This fabric combines nylon ripstop with a silicone impregnation process that creates an incredibly lightweight yet durable barrier. I've used silnylon tents in conditions ranging from desert sandstorms to mountain snowfall, and the material consistently performs exceptionally well.

The manufacturing process involves saturating nylon fibers with liquid silicone, which polymerizes to create a flexible, waterproof coating. This results in a fabric that's not only waterproof but also naturally resistant to UV degradation and extreme temperatures. The 30D ripstop nylon variants are particularly popular among ultralight backpackers.

Polyurethane-Coated Fabrics

PU-coated materials offer excellent value for money in the lightweight waterproof tent material category. These fabrics feature a polyurethane layer applied to one or both sides of the base material. While slightly heavier than silnylon, PU coatings provide reliable waterproofing at a more affordable price point.

Dyneema Composite Fabrics

For the ultimate in lightweight waterproof tent material, Dyneema composite fabrics (formerly Cuben Fiber) represent cutting-edge technology. These materials use ultra-high molecular weight polyethylene fibers laminated between polymer films. While expensive, they offer unmatched strength-to-weight ratios and complete waterproofing.

During extensive testing in harsh alpine conditions, I've found that ultra-lightweight options like 10D fabrics provide adequate protection for most three-season camping applications while significantly reducing pack weight.

Key Features to Look For

After years of field testing and comparing different materials, I've identified several critical features that distinguish superior lightweight waterproof tent material from mediocre options. These characteristics directly impact performance, durability, and user satisfaction in real-world camping scenarios.

Hydrostatic Head Rating

The hydrostatic head measurement indicates how much water pressure a fabric can withstand before leaking. Quality lightweight waterproof tent material should have a minimum rating of 1,500mm, with premium options reaching 3,000mm or higher. This rating directly correlates to protection in heavy rain conditions.

Denier Weight Classification

Denier measures fiber thickness and directly impacts both weight and durability. For lightweight waterproof tent material, I recommend 20D-70D fabrics for most applications. Lower deniers (15D-30D) work well for ultralight applications, while higher deniers (40D-70D) provide better durability for extended use.

Ripstop construction is another crucial feature that prevents small tears from spreading across the fabric. This grid pattern of heavier threads woven into the base material has saved my gear countless times during bushwhacking adventures. Quality waterproof nylon fabrics always incorporate this essential design element.

UV resistance becomes increasingly important for extended outdoor use. During my multi-week expeditions in high-altitude environments, I've observed significant degradation in untreated fabrics. Premium lightweight waterproof tent material includes UV stabilizers that maintain fabric integrity even after prolonged sun exposure.

Breathability, measured in grams per square meter per 24 hours, determines how well moisture vapor escapes from inside the tent. This feature prevents condensation buildup that can make sleeping bags damp and uncomfortable. Modern materials achieve breathability through microporous coatings that allow vapor transfer while blocking liquid water.

Top Product Reviews & Recommendations

Based on extensive field testing and performance analysis, I've compiled reviews of the best lightweight waterproof tent material options currently available. These recommendations span different price ranges and use cases, ensuring there's an option for every outdoor enthusiast.

Premium Choice: Emma Kites 20D Silnylon

This exceptional lightweight waterproof tent material represents the pinnacle of silicone-coated nylon technology. Weighing just 1.2 oz per square yard, it offers an impressive 3000mm hydrostatic head rating while maintaining excellent packability.

Best Value: 9KM DWLIFE 40D Ripstop Nylon

For budget-conscious adventurers seeking reliable lightweight waterproof tent material, this 40D ripstop nylon offers excellent performance at an unbeatable price point. The PU coating provides dependable waterproofing for three-season use.

Eco-Friendly Option: Vonty Ripstop Nylon

This environmentally conscious lightweight waterproof tent material combines sustainable manufacturing practices with high-performance characteristics. Perfect for eco-minded outdoor enthusiasts who refuse to compromise on quality.

Multi-Color Pack: 9KM DWLIFE 6-Color Set

For DIY enthusiasts and gear makers, this comprehensive pack offers six different colors of premium lightweight waterproof tent material. Each piece maintains consistent quality while providing creative flexibility for custom projects.

Complete Buying Guide

Selecting the right lightweight waterproof tent material requires careful consideration of multiple factors. Through years of testing and consulting with gear manufacturers, I've developed a systematic approach to help you make the best choice for your specific needs and budget constraints.

Climate and Season Considerations

Your primary camping environment significantly influences material selection. For desert conditions, UV resistance and breathability take priority. In wet climates like the Pacific Northwest, where I conduct most of my testing, waterproofing performance becomes paramount. Alpine environments demand materials that can handle temperature extremes without becoming brittle.

Three-season campers can opt for lighter weight lightweight waterproof tent material in the 20D-30D range, while four-season adventurers should consider more robust 40D-70D options. I've learned this distinction the hard way during unexpected late-season storms in the Cascade Mountains.

Budget Optimization Strategies

Quality lightweight waterproof tent material represents a long-term investment in your outdoor comfort and safety. While premium options like silnylon command higher prices, they often provide better value over time due to superior durability and performance characteristics.

Pro Tip:

Consider purchasing slightly more material than immediately needed. Having extra lightweight waterproof tent material allows for repairs and modifications while taking advantage of bulk pricing.

Essential Specification Checklist

- Hydrostatic head rating ≥ 1,500mm

- Ripstop construction for tear resistance

- UV stabilizers for sun protection

- Breathability rating for condensation control

- Temperature range compatibility

Weight considerations extend beyond the fabric itself. Factor in coating treatments, seam sealing requirements, and hardware compatibility when calculating total system weight. The best lightweight waterproof tent material optimizes all these elements for your specific application.

Maintenance & Care Tips

Proper maintenance extends the lifespan of your lightweight waterproof tent material significantly. Through years of gear testing and field experience, I've developed proven techniques that keep fabrics performing at peak levels even after extensive use in challenging conditions.

Cleaning and Storage Protocols

Never underestimate the importance of proper cleaning for lightweight waterproof tent material. Dirt, salt, and organic matter can degrade coatings over time. I always clean my gear immediately after returning from trips, using lukewarm water and specialized technical fabric cleaners that won't strip protective treatments.

Avoid conventional detergents and fabric softeners, which can compromise waterproof coatings. Instead, use products specifically designed for technical fabrics. After washing, ensure complete drying before storage to prevent mold and mildew formation that can permanently damage the material.

DWR Treatment Restoration

The durable water repellent finish on lightweight waterproof tent material gradually wears away with use and UV exposure. When water stops beading on the surface and instead soaks into the fabric, it's time for DWR restoration. This process involves applying specialized treatments that restore the surface's water-repelling properties.

I typically recommend reapplying DWR treatment annually for heavily used gear, or whenever you notice decreased water repellency. Heat activation after application, using either a household iron or clothes dryer, ensures optimal performance of the new treatment.

Field Repair Essentials:

Always carry repair tape and seam sealer when using lightweight waterproof tent material in the field. Small tears can quickly become major problems if not addressed immediately. Quality repair materials weigh virtually nothing but can save an entire expedition.

Regular inspection of seams, stress points, and coating integrity helps identify potential issues before they become serious problems. During my annual gear reviews each spring, I thoroughly examine all tent materials and perform necessary maintenance to ensure reliability for the upcoming season.

Conclusion

After extensively researching and field-testing various options, I'm confident that understanding lightweight waterproof tent material is crucial for any serious outdoor enthusiast. The evolution of fabric technology has created unprecedented opportunities for comfortable, reliable shelter systems that don't burden your pack weight.

The key to success lies in matching material characteristics to your specific needs and environmental conditions. Whether you choose premium silnylon for ultralight backpacking or more affordable PU-coated options for car camping, the principles of proper selection and maintenance remain consistent.

Quality lightweight waterproof tent material represents an investment in your outdoor comfort and safety. By following the guidelines in this comprehensive guide, you'll be well-equipped to make informed decisions that enhance your camping experiences for years to come. Remember that the best material is the one that keeps you dry, comfortable, and confident in the outdoors.

Ready to Upgrade Your Gear?

Start your journey with proven lightweight waterproof tent material that delivers reliable performance in any conditions.

Explore All Lightweight Tent Materials