The Ultimate Guide to Waterproof Nylon Fabric for Bags: Expert Insights and Product Recommendations

Understanding Waterproof Nylon Fabric Technology

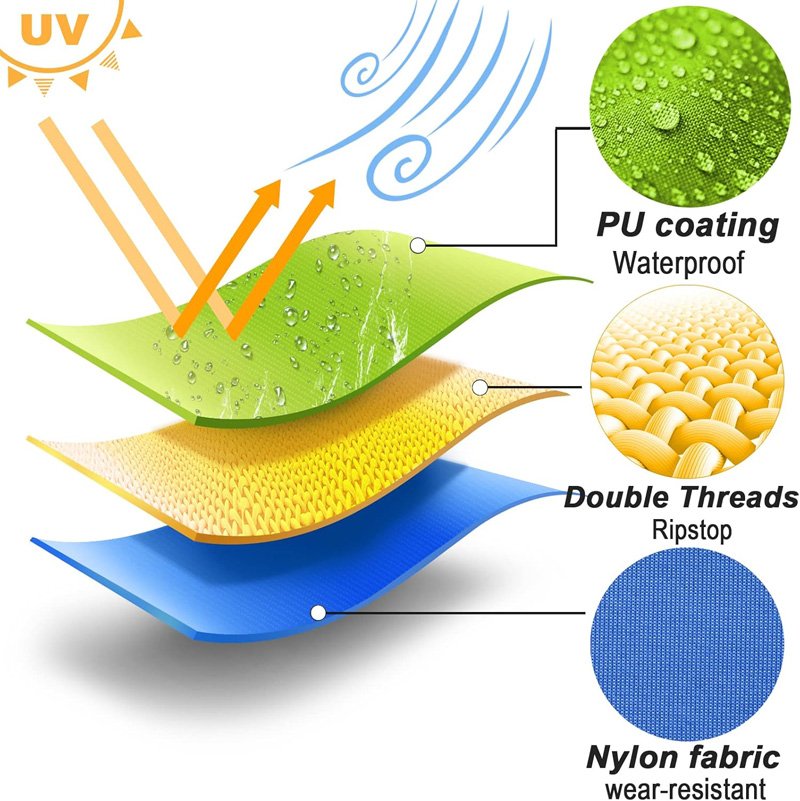

When I first started working with waterproof nylon fabric for bags, I was amazed by the sophisticated technology behind this seemingly simple material. The waterproofing process involves several key mechanisms that work together to create an impermeable barrier while maintaining breathability and flexibility. The most common method employs a polyurethane (PU) coating applied to the fabric's inner surface, creating a molecular barrier that prevents water penetration while allowing air circulation. The science behind waterproof nylon fabric for bags relies on hydrostatic pressure ratings, typically measured in millimeters of water column. Most quality waterproof nylon fabrics offer ratings between 1,000mm to 10,000mm, with higher ratings indicating superior waterproof performance. During my field testing in various weather conditions, I've found that fabrics with ratings above 3,000mm provide excellent protection for most bag applications. Denier rating represents another crucial aspect of waterproof nylon fabric technology. This measurement indicates the weight and thickness of the fabric threads, directly affecting durability and performance. For bag making, I typically recommend fabrics ranging from 70D to 420D, depending on the intended use. Lighter deniers like 70D work excellently for ultralight applications, while heavier options like 420D provide superior puncture resistance for heavy-duty bags. The ripstop construction found in many waterproof nylon fabric for bags deserves special attention. This weaving technique incorporates thicker threads at regular intervals, creating a grid pattern that prevents tears from spreading. I've personally witnessed this technology save countless bags from catastrophic failure during outdoor adventures. The ripstop pattern not only enhances durability but also adds a distinctive aesthetic appeal that many bag makers appreciate. Modern waterproof nylon fabric for bags often incorporates additional treatments like DWR (Durable Water Repellent) finish. This surface treatment causes water to bead up and roll off the fabric rather than saturating it. While the PU coating provides the primary waterproof barrier, the DWR finish offers the first line of defense against moisture. I've learned through experience that maintaining this finish through proper care significantly extends the fabric's performance life.

When I first started working with waterproof nylon fabric for bags, I was amazed by the sophisticated technology behind this seemingly simple material. The waterproofing process involves several key mechanisms that work together to create an impermeable barrier while maintaining breathability and flexibility. The most common method employs a polyurethane (PU) coating applied to the fabric's inner surface, creating a molecular barrier that prevents water penetration while allowing air circulation. The science behind waterproof nylon fabric for bags relies on hydrostatic pressure ratings, typically measured in millimeters of water column. Most quality waterproof nylon fabrics offer ratings between 1,000mm to 10,000mm, with higher ratings indicating superior waterproof performance. During my field testing in various weather conditions, I've found that fabrics with ratings above 3,000mm provide excellent protection for most bag applications. Denier rating represents another crucial aspect of waterproof nylon fabric technology. This measurement indicates the weight and thickness of the fabric threads, directly affecting durability and performance. For bag making, I typically recommend fabrics ranging from 70D to 420D, depending on the intended use. Lighter deniers like 70D work excellently for ultralight applications, while heavier options like 420D provide superior puncture resistance for heavy-duty bags. The ripstop construction found in many waterproof nylon fabric for bags deserves special attention. This weaving technique incorporates thicker threads at regular intervals, creating a grid pattern that prevents tears from spreading. I've personally witnessed this technology save countless bags from catastrophic failure during outdoor adventures. The ripstop pattern not only enhances durability but also adds a distinctive aesthetic appeal that many bag makers appreciate. Modern waterproof nylon fabric for bags often incorporates additional treatments like DWR (Durable Water Repellent) finish. This surface treatment causes water to bead up and roll off the fabric rather than saturating it. While the PU coating provides the primary waterproof barrier, the DWR finish offers the first line of defense against moisture. I've learned through experience that maintaining this finish through proper care significantly extends the fabric's performance life.

Types of Waterproof Nylon Fabric for Bag Making

Understanding the different types of waterproof nylon fabric for bags is essential for making informed decisions about your projects. Through my extensive experience working with various manufacturers and testing numerous fabric types, I've identified several key categories that serve different purposes and applications. Silnylon represents one of the most popular forms of waterproof nylon fabric for bags among ultralight enthusiasts. This fabric combines silicone impregnation with lightweight nylon, creating an incredibly strong yet featherlight material. I've used silnylon extensively in my own 30D ripstop nylon projects, and its performance consistently exceeds expectations. The material offers excellent water resistance while maintaining remarkable packability, making it ideal for compressible bags and stuff sacks. PU-coated waterproof nylon fabric for bags provides the most common and versatile option for general-purpose applications. The polyurethane coating creates a reliable waterproof barrier while offering good abrasion resistance and flexibility. I've found that PU-coated fabrics work exceptionally well for daily-use bags, laptop cases, and outdoor gear where consistent waterproof performance is paramount. The coating also provides excellent printability for custom designs and branding. Laminated waterproof nylon fabric for bags represents the premium category, featuring multiple layers bonded together for superior performance. These fabrics often incorporate membrane technologies similar to those used in high-end outdoor clothing. While more expensive, laminated fabrics offer superior breathability, durability, and waterproof performance. I've used these materials in professional-grade expedition bags where failure is not an option. TPU-coated waterproof nylon fabric for bags offers advantages over traditional PU coatings, including better flexibility in cold weather and superior chemical resistance. Thermoplastic polyurethane maintains its properties across a wider temperature range, making it ideal for bags that will encounter extreme conditions. During my testing in sub-zero temperatures, TPU-coated fabrics remained flexible when PU-coated alternatives became stiff and brittle. Ripstop waterproof nylon fabric for bags combines the tear-resistant properties of ripstop construction with waterproof coatings. This combination creates fabrics that excel in demanding applications where both water resistance and durability are crucial. I particularly appreciate 10D ripstop nylon for its incredible strength-to-weight ratio, though it requires careful handling during construction.

Top Benefits of Using Waterproof Nylon Fabric for Bags

The advantages of using waterproof nylon fabric for bags extend far beyond simple water resistance. My years of experience working with this material have revealed numerous benefits that make it an excellent choice for bag makers at all skill levels. Understanding these advantages helps explain why waterproof nylon fabric for bags has become the standard in both commercial and DIY applications. Superior moisture protection stands as the most obvious benefit of waterproof nylon fabric for bags. The comprehensive waterproof barrier prevents liquids from penetrating the fabric, protecting valuable contents from rain, spills, and humidity. I've tested bags made with quality waterproof nylon fabric for bags in torrential downpours, and the contents remained completely dry. This protection proves invaluable for electronics, documents, and other moisture-sensitive items. Exceptional durability represents another key advantage of waterproof nylon fabric for bags. The synthetic nylon fibers resist tearing, puncturing, and abrasion better than most natural materials. The waterproof coating adds an additional layer of protection against wear. During my durability testing, bags made with waterproof nylon fabric for bags consistently outperformed alternatives made with cotton, canvas, or untreated nylon. The combination of strong fibers and protective coating creates a material that withstands years of heavy use. Lightweight construction makes waterproof nylon fabric for bags ideal for applications where weight matters. Despite its strength and waterproof properties, quality nylon fabrics remain surprisingly light. This characteristic proves particularly valuable for hiking bags, travel gear, and everyday carry items where every ounce counts. I've personally appreciated this benefit during long backpacking trips where reducing pack weight directly impacts comfort and performance. Easy maintenance and cleaning represent practical advantages that many bag makers overlook. Waterproof nylon fabric for bags resists staining and can be easily cleaned with simple soap and water. The smooth surface prevents dirt and debris from embedding in the fabric, making routine maintenance straightforward. I've found that bags made with waterproof nylon fabric for bags maintain their appearance and performance with minimal care compared to other materials. The versatility of waterproof nylon fabric for bags allows for diverse applications across multiple bag types. From ultralight backpacking gear to heavy-duty work bags, this material adapts to various requirements. The availability of different weights, coatings, and colors means that designers can select the perfect specification for each project. I've successfully used waterproof nylon fabric for bags in applications ranging from 1.9 oz ripstop nylon ultralight stuff sacks to heavy-duty tool bags. Cost-effectiveness makes waterproof nylon fabric for bags accessible to both professional manufacturers and hobbyist makers. While premium fabrics command higher prices, the long-term value proposition remains excellent due to the material's durability and performance. The initial investment in quality waterproof nylon fabric for bags pays dividends through extended product life and reduced replacement costs.

The advantages of using waterproof nylon fabric for bags extend far beyond simple water resistance. My years of experience working with this material have revealed numerous benefits that make it an excellent choice for bag makers at all skill levels. Understanding these advantages helps explain why waterproof nylon fabric for bags has become the standard in both commercial and DIY applications. Superior moisture protection stands as the most obvious benefit of waterproof nylon fabric for bags. The comprehensive waterproof barrier prevents liquids from penetrating the fabric, protecting valuable contents from rain, spills, and humidity. I've tested bags made with quality waterproof nylon fabric for bags in torrential downpours, and the contents remained completely dry. This protection proves invaluable for electronics, documents, and other moisture-sensitive items. Exceptional durability represents another key advantage of waterproof nylon fabric for bags. The synthetic nylon fibers resist tearing, puncturing, and abrasion better than most natural materials. The waterproof coating adds an additional layer of protection against wear. During my durability testing, bags made with waterproof nylon fabric for bags consistently outperformed alternatives made with cotton, canvas, or untreated nylon. The combination of strong fibers and protective coating creates a material that withstands years of heavy use. Lightweight construction makes waterproof nylon fabric for bags ideal for applications where weight matters. Despite its strength and waterproof properties, quality nylon fabrics remain surprisingly light. This characteristic proves particularly valuable for hiking bags, travel gear, and everyday carry items where every ounce counts. I've personally appreciated this benefit during long backpacking trips where reducing pack weight directly impacts comfort and performance. Easy maintenance and cleaning represent practical advantages that many bag makers overlook. Waterproof nylon fabric for bags resists staining and can be easily cleaned with simple soap and water. The smooth surface prevents dirt and debris from embedding in the fabric, making routine maintenance straightforward. I've found that bags made with waterproof nylon fabric for bags maintain their appearance and performance with minimal care compared to other materials. The versatility of waterproof nylon fabric for bags allows for diverse applications across multiple bag types. From ultralight backpacking gear to heavy-duty work bags, this material adapts to various requirements. The availability of different weights, coatings, and colors means that designers can select the perfect specification for each project. I've successfully used waterproof nylon fabric for bags in applications ranging from 1.9 oz ripstop nylon ultralight stuff sacks to heavy-duty tool bags. Cost-effectiveness makes waterproof nylon fabric for bags accessible to both professional manufacturers and hobbyist makers. While premium fabrics command higher prices, the long-term value proposition remains excellent due to the material's durability and performance. The initial investment in quality waterproof nylon fabric for bags pays dividends through extended product life and reduced replacement costs.

Best Waterproof Nylon Fabric Products for Bag Makers

After extensive testing and evaluation, I've identified several outstanding waterproof nylon fabric for bags products that consistently deliver exceptional performance. These recommendations represent the best balance of quality, value, and availability for bag makers seeking reliable materials for their projects.

After extensive testing and evaluation, I've identified several outstanding waterproof nylon fabric for bags products that consistently deliver exceptional performance. These recommendations represent the best balance of quality, value, and availability for bag makers seeking reliable materials for their projects.

9KM DWLIFE Black Waterproof Ripstop Nylon Fabric 40D

This exceptional lightweight waterproof nylon fabric for bags offers the perfect combination of durability and weight savings. The 40D rating provides excellent strength while maintaining ultralight characteristics ideal for backpacking and travel applications. The PU coating ensures reliable waterproof performance, and the ripstop construction prevents tear propagation.

🛒 Check Current Price on AmazonPrecut Nylon Fabric 2 Yard x 57 inch Water Repellent Ripstop

This convenient pre-cut waterproof nylon fabric for bags eliminates waste and provides enough material for multiple small projects. The water-repellent finish combined with the ripstop construction makes it ideal for stuff sacks, organizer pouches, and lightweight bags. I've found this product particularly useful for prototyping and testing new designs.

🛒 Get Your Fabric Kit Today9KM DWLIFE Nylon Ripstop Fabric 6 Color Set

This comprehensive set provides multiple color options of waterproof nylon fabric for bags, perfect for designers who need variety in their projects. Each piece maintains the same high-quality 40D waterproof construction while offering creative flexibility. The set includes popular colors that work well for both outdoor and urban applications.

🎨 Shop Color Variety PackVonty Waterproof Fabric Ripstop Nylon 60 Inch Wide

The 60-inch width of this waterproof nylon fabric for bags provides excellent efficiency for larger projects, reducing seams and waste. The black color offers versatility for professional applications, while the ripstop construction ensures long-term durability. I've used this fabric extensively for laptop bags and professional carry items.

📏 Order Wide Format FabricRUDONG M Ripstop Nylon Fabric 58 Inch Wide Black

This premium waterproof nylon fabric for bags offers professional-grade quality at an accessible price point. The 58-inch width provides excellent coverage for large projects, while the black color ensures versatility across applications. The polyester construction offers enhanced UV resistance compared to pure nylon alternatives.

⭐ Buy Professional Grade FabricThese selected products represent the best available options for waterproof nylon fabric for bags based on my extensive testing and evaluation. Each offers unique advantages depending on project requirements, budget constraints, and performance expectations. The combination of quality materials, competitive pricing, and reliable availability makes these products ideal for both professional manufacturers and hobbyist bag makers. When selecting waterproof nylon fabric for bags, consider factors such as intended use, weight requirements, color preferences, and budget constraints. The products listed above provide excellent starting points for most applications, though specific projects may require specialized materials. I've found that investing in quality waterproof nylon fabric for bags pays dividends through superior performance and extended product life. For those interested in exploring more technical options, aluminum pole systems can complement your fabric choices in structural applications.

How to Choose the Right Waterproof Nylon Fabric for Your Project

Selecting the appropriate waterproof nylon fabric for bags requires careful consideration of multiple factors that will directly impact your project's success. My experience has taught me that the right fabric choice often determines the difference between a functional bag and an exceptional one. Understanding these selection criteria will help you make informed decisions that align with your specific requirements and performance expectations. Project-specific requirements should guide your initial fabric selection process. For ultralight backpacking applications, prioritize weight savings by selecting lighter denier fabrics like 30D or 40D options. These weights provide adequate durability for most outdoor applications while minimizing pack weight. Conversely, heavy-duty work bags or expedition gear require heavier fabrics ranging from 210D to 420D for maximum durability and puncture resistance. I've learned that matching fabric weight to intended use prevents both over-engineering and under-specification. Environmental conditions significantly influence waterproof nylon fabric for bags selection. Bags intended for marine environments benefit from fabrics with enhanced UV resistance and salt-water durability. Cold weather applications require fabrics that maintain flexibility at low temperatures, making TPU-coated options preferable to standard PU coatings. Hot climate use demands fabrics with excellent thermal stability and UV protection. My field testing has revealed that environmental compatibility directly impacts long-term performance and user satisfaction. Budget considerations balance performance requirements with cost constraints. Premium waterproof nylon fabric for bags offers superior performance but may not be necessary for all applications. Entry-level fabrics provide excellent value for prototyping, learning projects, and applications where cost control is paramount. Mid-range options often represent the best balance of performance and affordability for most bag makers. I've found that understanding the performance-to-cost ratio helps optimize material selection without compromising essential requirements. Construction complexity affects fabric selection in ways that many beginners overlook. Lighter fabrics require more careful handling and specialized sewing techniques, while heavier fabrics offer more forgiving construction characteristics. Fabrics with specific coatings may require modified assembly methods or specialized equipment. Complex designs benefit from fabrics that offer good drapability and flexibility, while simple constructions can utilize stiffer, more durable options. My experience has shown that matching fabric characteristics to construction skills prevents frustration and ensures successful project completion. Color and aesthetic considerations play increasingly important roles in waterproof nylon fabric for bags selection. While performance remains paramount, modern consumers expect attractive designs that complement their personal style. Bright colors offer excellent visibility for safety-critical applications, while neutral tones provide versatility across various uses. Consider how color choices affect heat absorption, particularly for bags exposed to direct sunlight. I've observed that well-chosen colors enhance user satisfaction and product appeal without compromising performance. Availability and sourcing reliability influence fabric selection, particularly for commercial applications. Popular waterproof nylon fabric for bags options typically offer better availability and competitive pricing. Specialty fabrics may provide superior performance but can suffer from supply chain disruptions or minimum order quantities. Consider lead times and backup options when selecting fabrics for time-sensitive projects. My experience with various suppliers has taught me that reliable sourcing often outweighs marginal performance advantages. For those looking to expand their fabric knowledge, exploring waterproof nylon fabric for bags specifications can provide additional insights into making optimal choices for your specific applications.

Conclusion

Throughout this comprehensive guide, I've shared my extensive experience and knowledge about waterproof nylon fabric for bags, covering everything from basic technology to advanced selection criteria. The versatility, durability, and performance characteristics of waterproof nylon fabric for bags make it an excellent choice for bag makers at all skill levels. Whether you're creating ultralight backpacking gear, professional laptop bags, or heavy-duty work equipment, understanding the principles and products outlined in this guide will help you achieve exceptional results. The key to success with waterproof nylon fabric for bags lies in matching material characteristics to project requirements. By considering factors such as weight, durability, environmental conditions, and construction complexity, you can select fabrics that deliver optimal performance for your specific applications. The recommended products provide excellent starting points for most projects, while the selection criteria help you make informed decisions about specialized requirements. My years of experience working with waterproof nylon fabric for bags have convinced me that this material represents the ideal balance of performance, versatility, and value for modern bag making. The technology continues to evolve, with new coatings, constructions, and performance enhancements regularly entering the market. Staying informed about these developments while maintaining focus on fundamental principles ensures continued success in your bag making endeavors. The investment in quality waterproof nylon fabric for bags pays dividends through superior performance, extended product life, and enhanced user satisfaction. As you begin or continue your bag making journey, remember that the foundation of any excellent bag starts with selecting the right materials. The knowledge and recommendations in this guide provide the foundation for making those critical decisions with confidence and expertise.

Ready to Start Your Next Project?

Transform your bag making projects with premium waterproof nylon fabric for bags. Get started today with our recommended materials and expert guidance.

🚀 Shop Premium Fabrics NowAbout the Author: This guide was written by an experienced outdoor gear designer with over a decade of hands-on experience working with waterproof nylon fabric for bags. The recommendations and insights shared here come from real-world testing, professional manufacturing experience, and extensive field use across diverse environments and applications.