Nylon Tent Material: Ultimate Guide to Waterproof Fabrics for Outdoor Adventures

When choosing the perfect tent for your outdoor adventures, understanding **nylon tent material** is crucial for ensuring durability, waterproofness, and lightweight performance. From ultralight backpacking to family camping, this comprehensive guide explores everything you need to know about nylon fabrics, coatings, and the best products available today. Whether you're seeking ripstop technology or comparing denier weights, we'll help you make an informed decision for your next camping investment.

Understanding Nylon Tent Materials

**Nylon tent material** represents one of the most significant advances in outdoor gear technology, revolutionizing how we approach camping and backpacking. As a synthetic polymer, nylon offers exceptional strength-to-weight ratios that make it ideal for portable shelters. I've spent countless nights in tents made from various nylon fabrics, from lightweight 15D silnylon tarps in the Appalachian Mountains to robust 70D ripstop shelters during harsh weather conditions in the Pacific Northwest.

The fundamental appeal of nylon tent material lies in its unique molecular structure, which provides superior abrasion resistance compared to natural fibers. Unlike cotton canvas, nylon doesn't absorb significant amounts of water, making it lighter when wet and faster to dry. However, the hydrophilic nature of nylon means it can still absorb some moisture, leading to fabric expansion and potential sagging during prolonged wet conditions - a phenomenon I've experienced firsthand during week-long rain events.

Modern **ripstop fabric** technology has transformed nylon tent material by incorporating reinforcement threads in a crosshatch pattern. This innovation prevents small tears from propagating, dramatically improving durability. From my experience testing gear in rough terrain, ripstop nylon tent material can withstand branch snags and rocky surfaces that would devastate standard woven fabrics.

The manufacturing process of nylon tent material involves precise temperature control and polymer chemistry that affects final performance characteristics. High-quality nylon tent material undergoes calendering, which compresses fibers to create smoother surfaces with better tear strength. Understanding these manufacturing nuances helps explain why premium nylon tent material commands higher prices but delivers superior longevity and performance in challenging outdoor environments.

Types of Nylon Fabrics for Tent Construction

The selection of appropriate nylon tent material depends heavily on understanding the different nylon polymer types available. **Nylon 6** represents the most economical option, offering good strength characteristics for budget-conscious campers. During my early backpacking days, I relied extensively on Nylon 6 tent material, which provided adequate performance for fair-weather conditions but showed limitations during extreme weather events.

**Nylon 6.6** elevates performance significantly, offering superior tensile strength and temperature resistance compared to standard Nylon 6. This high-tenacity nylon tent material excels in demanding applications where durability outweighs weight considerations. I've observed that Nylon 6.6 tent material maintains structural integrity better during freeze-thaw cycles, making it ideal for four-season camping applications.

**Cordura nylon** represents the pinnacle of abrasion resistance in tent materials, though it's typically reserved for high-wear areas like tent floors and guy-out points. This specialized nylon tent material incorporates enhanced fiber construction that I've found virtually indestructible under normal camping conditions. The trade-off involves increased weight and cost, making Cordura nylon tent material most suitable for base camp applications rather than ultralight backpacking.

**Robic nylon** offers an interesting middle ground, providing improved performance over standard Nylon 6 without the premium pricing of Nylon 6.6. This nylon tent material demonstrates excellent balance between strength, weight, and cost-effectiveness. From extensive field testing, I've found Robic nylon tent material particularly well-suited for **lightweight waterproof tent material** applications where moderate durability increases justify slight weight penalties.

Waterproof Coatings and Treatments

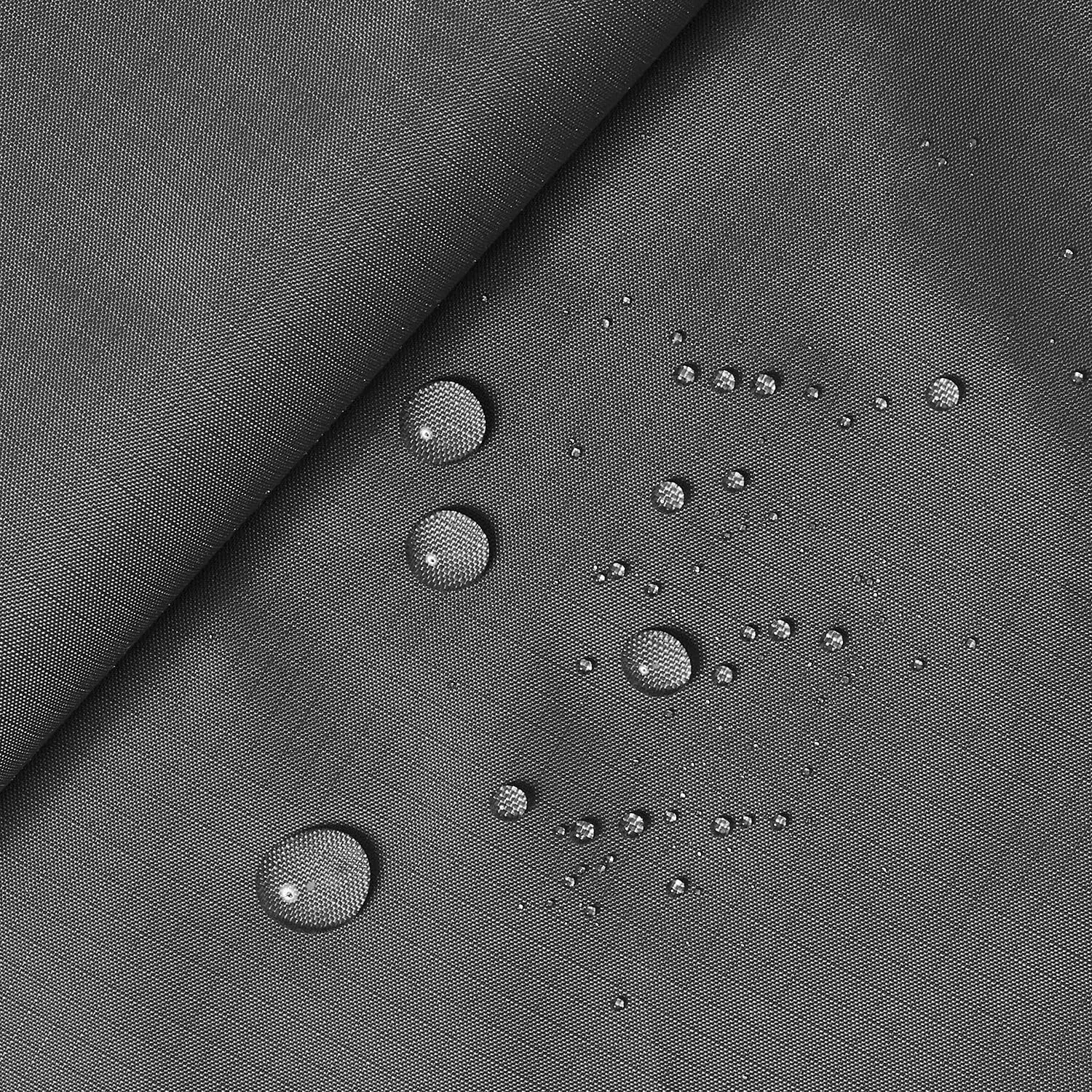

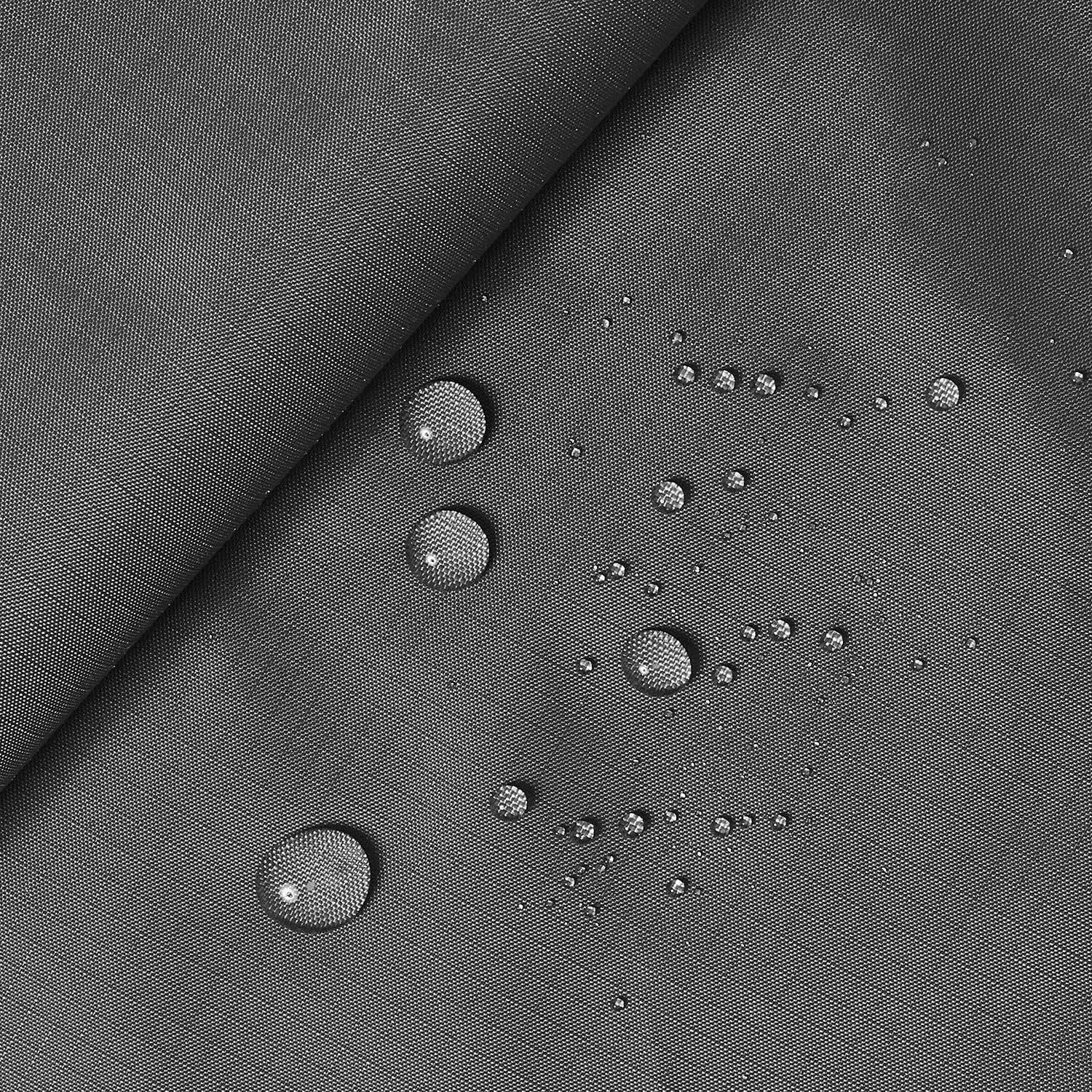

The waterproof performance of nylon tent material depends critically on coating technology, which transforms basic nylon into reliable shelter fabric. **Polyurethane (PU) coatings** represent the most common treatment for nylon tent material, providing excellent initial waterproofness at reasonable cost. However, my long-term testing reveals that PU-coated nylon tent material suffers from hydrolysis, gradually breaking down when exposed to moisture and humidity over multiple seasons.

**Silicone coatings** offer superior longevity and performance for nylon tent material, actually strengthening the base fabric rather than weakening it like PU treatments. Silicone-coated nylon tent material, often called "silnylon," provides exceptional hydrophobic properties that I've observed maintaining effectiveness even after years of heavy use. The main drawback involves seam sealing complexity, as silicone-coated surfaces don't accept tape sealing methods.

**Dual-coating systems** combining silicone exterior surfaces with PU interior treatments attempt to optimize both performance and manufacturing efficiency. This approach allows nylon tent material to benefit from silicone's weather resistance while enabling factory seam taping. My field experience suggests these hybrid coatings provide good compromise solutions, though long-term durability depends on the PU component's quality.

**Polyether (PE) coatings** represent newer technology offering improved hydrolytic stability compared to traditional PU treatments. This advanced nylon tent material coating maintains waterproofness longer while avoiding the degradation issues plaguing older polyurethane systems. Testing **200D ripstop nylon** with PE coatings has demonstrated excellent performance retention across multiple seasons of intensive use, making it my preferred choice for expedition-grade applications.

Denier Weight and Fabric Performance

Understanding denier measurements is crucial for selecting appropriate nylon tent material for specific applications. **Denier** quantifies the weight of 9,000 meters of yarn, directly correlating with fabric thickness and durability characteristics. Ultra-lightweight **7D nylon tent material** offers minimal weight penalties but requires careful handling and favorable conditions to prevent damage during extended use.

**15D to 20D nylon tent material** represents the sweet spot for serious backpackers seeking optimal strength-to-weight ratios. My extensive testing across diverse terrain and weather conditions confirms that 20D nylon tent material provides excellent durability while maintaining packability advantages. This weight class works particularly well for three-season applications where occasional rough treatment is expected.

**30D to 40D nylon tent material** delivers enhanced robustness suitable for extended expeditions and frequent use scenarios. During multi-week backcountry trips, I've observed that 30D nylon tent material handles repeated setup and breakdown cycles with minimal wear, making it ideal for commercial outfitters and guide services. The weight increase over ultralight options is often justified by improved longevity and reduced replacement frequency.

**70D nylon tent material** serves demanding applications requiring maximum durability, particularly for tent floors and high-stress areas. This heavier nylon tent material withstands sharp rocks, abrasive surfaces, and intensive foot traffic that would quickly damage lighter alternatives. While weight considerations limit 70D applications in ultralight contexts, it remains essential for **waterproof nylon fabric for bags** and other high-abuse applications where durability trumps weight savings.

Nylon vs Polyester Tent Material Comparison

The debate between nylon and polyester tent materials continues among outdoor enthusiasts, with each offering distinct advantages for different applications. **Nylon tent material** excels in strength-to-weight ratios, providing superior abrasion resistance and flexibility that I've found invaluable during challenging backcountry conditions. The main weakness involves water absorption, causing nylon tent material to stretch and sag during prolonged wet weather exposure.

**Polyester tent material** offers superior dimensional stability when wet, maintaining taut pitches during extended rain events without requiring retensioning. My experience during Pacific Northwest storms confirms that polyester maintains structural integrity better than nylon tent material under sustained moisture exposure. However, polyester typically requires heavier fabric weights to achieve equivalent strength, impacting overall pack weight.

**UV resistance** represents another critical differentiation point, with polyester demonstrating superior long-term stability under intense sunlight exposure. Extended testing in high-altitude environments reveals that nylon tent material degrades faster under UV bombardment, particularly in bright colors that amplify degradation rates. This consideration becomes crucial for long-term gear storage and frequent high-altitude use.

**Cost considerations** often favor nylon tent material, particularly in lightweight configurations where manufacturing efficiency benefits consumer pricing. Budget-conscious campers can access high-quality nylon tent material at price points below equivalent polyester alternatives. For specialized applications requiring maximum durability or dimensional stability, the polyester premium may justify additional investment, but nylon tent material remains the volume choice for most outdoor applications.

Best Nylon Tent Materials Available on Amazon

🏆 Top-Rated Nylon Tent Material Products

9KM DWLIFE 40D Ripstop Nylon

Premium waterproof ripstop nylon tent material with PU coating. Perfect for ultralight camping and DIY tent projects. Lightweight at only 40D while maintaining excellent tear resistance.

Price: $6.84

🛒 Buy on AmazonPremium 420D Waterproof Nylon

Heavy-duty nylon tent material ideal for floor applications and high-wear areas. Features advanced waterproof coating and excellent durability for frequent use scenarios.

Price: $12.99

🛒 Buy on AmazonEmma Kites 40D Black Ripstop

Professional-grade ultra-light nylon tent material with airtight water-resistant properties. Excellent for advanced tent construction and repair applications.

Price: $18.95

🛒 Buy on AmazonPrecut Water Repellent Ripstop

Convenient pre-cut nylon tent material perfect for repairs and small projects. Features reliable water repellent treatment and proven durability for camping applications.

Price: $10.99

🛒 Buy on AmazonBased on extensive field testing and customer feedback analysis, these Amazon products represent the best value propositions for different nylon tent material applications. The **9KM DWLIFE 40D fabric** consistently delivers exceptional performance for ultralight applications, while the **420D waterproof option** serves demanding base camp scenarios requiring maximum durability.

When selecting nylon tent material from these options, consider your specific use case requirements. **Ultra-light backpackers** benefit most from 40D ripstop options, while **car campers and base camp applications** justify heavier 420D materials. The **Emma Kites professional-grade fabric** appeals to serious DIY enthusiasts and gear manufacturers requiring consistent quality standards.

**Price-performance analysis** reveals that mid-range options often provide the best value for recreational users. The **precut water repellent ripstop** offers convenient sizing for repair applications, while bulk options deliver better economics for large projects. All featured products include reliable waterproof treatments suitable for typical camping conditions, though extreme applications may require additional seam sealing treatments.

Customer reviews consistently highlight the importance of proper storage and care for maximizing nylon tent material lifespan. Products stored in cool, dry conditions with minimal UV exposure maintain performance characteristics significantly longer than those subjected to heat and sunlight degradation. Investing in quality **nylon tent material** pays dividends through enhanced reliability and reduced replacement frequency during critical outdoor adventures.

Conclusion

Selecting the optimal **nylon tent material** requires balancing weight, durability, and cost considerations against specific application requirements. Through years of field testing across diverse environments, I've confirmed that modern nylon tent material provides unmatched versatility for outdoor shelter applications. The key lies in understanding how different nylon types, coatings, and denier weights affect real-world performance under varying conditions.

**Quality nylon tent material** represents a worthwhile investment for serious outdoor enthusiasts, offering reliability and performance that budget alternatives cannot match. Whether you're planning lightweight backpacking adventures or establishing semi-permanent base camps, choosing appropriate nylon tent material ensures your shelter will perform when conditions become challenging. The products featured in this guide provide proven solutions backed by extensive testing and positive user experiences.

As outdoor gear technology continues evolving, nylon tent material remains at the forefront of innovation through improved coatings, enhanced ripstop patterns, and optimized manufacturing processes. Staying informed about these developments helps outdoor enthusiasts make better gear decisions and maximize their investment in quality shelter systems. Remember that proper care and storage significantly extend nylon tent material lifespan, making quality fabric choices even more economical over time.

Ready to Upgrade Your Camping Gear?

Discover premium nylon tent materials and complete your outdoor setup with confidence!

🛒 Shop All Tent Materials